How Big Is a Sheet of Plywood? Everything You Need to Know

Plywood is a crucial product made use of in lots of sectors, from building to furnishings making. Comprehending its dimension is essential, however there's more to it than just knowing its dimensions.

What Is Plywood?

Plywood is a sheet of wood made by layering slim veneers that are bound with each other using adhesives. It's understood for its strength, versatility, and durability, making it a popular material for different applications, consisting of flooring, roof covering, and furnishings. However, the dimension of the sheet can differ based on your requirements and the particular application.

Standard Sheet Size

The most common dimension for a sheet of this product is 4 feet by 8 feet (4' x 8'). This basic dimension is typically referred to as a "4x8 sheet." A single sheet covers a location of 32 square feet, making it excellent for projects such as wall surface sheathing, subfloors, and cabinets.

Why 4' x 8'?

The 4x8 dimension is widely made use of since it fits perfectly with the spacing of flooring joists, roofing system trusses, and wall surface studs. This standardization enables simpler installment and guarantees consistency throughout jobs. Whether you're constructing a home or crafting custom-made furnishings, this dimension streamlines planning.

Variations in Sheet Sizes

While 4' x 8' is the requirement, sheets come in various other sizes too:

4' x 4' Sheets: Perfect for smaller jobs or limited spaces.

5' x 5' Sheets: Often made use of for cabinet-making or furnishings jobs.

Custom Sizes: Some vendors supply personalized dimensions to match details demands.

Thickness of Sheets

Sheets are available in numerous thicknesses, normally ranging from 1/8 inch to 1 inch or even more. Common thicknesses include:

1/4 inch

3/8 inch

1/2 inch

5/8 inch

3/4 inch

The density you choose depends on your task. Thicker sheets are often made use of for structural applications, such as floorings and roof coverings, while thinner ones are better suited for decorative jobs.

Uses of Plywood

Plywood is widely made use of in a range of fields. A few of the most common applications consist of:

1. Construction

In construction, it's used for subflooring, wall sheathing, and roofing. Its stamina and ability to endure hefty tons make it a suitable material for these structural requirements.

2. Furniture Making

For furnishings projects, this material is treasured for its longevity, aesthetic allure, and cost-effectiveness. It's commonly utilized to create cabinets, tables, shelfs, and a lot more.

3. Interior Design

This material is also made use of for interior decoration purposes, including paneling, floor covering, and other imaginative applications. With the ideal finish, it can include a modern, elegant touch to any type of room.

4. Packaging

Plywood is used in the production of durable pet crates and containers for shipping and storage, offering a solid, reputable solution for commercial applications.

5. Boat Building

In watercraft structure, it's made use of to produce the hull because of its lightweight yet long lasting residential or commercial properties, making it perfect for marine applications.

Tools for Working with Plywood

When working with this versatile product, it's important to utilize the right tools. Below are several of the key makers and equipment that can make your projects a lot more efficient.

1. Knife Grinding Machines

Knife grinding makers are essential for keeping the intensity of the blades made use of in cutting. These makers make certain that the blades can work successfully, minimizing deterioration during the cutting procedure.

Knife Grinder Machiness are developed for grinding and developing the blades that are utilized to cut sheets. They aid make certain accuracy and improve efficiency by maintaining sharp blades for longer durations.

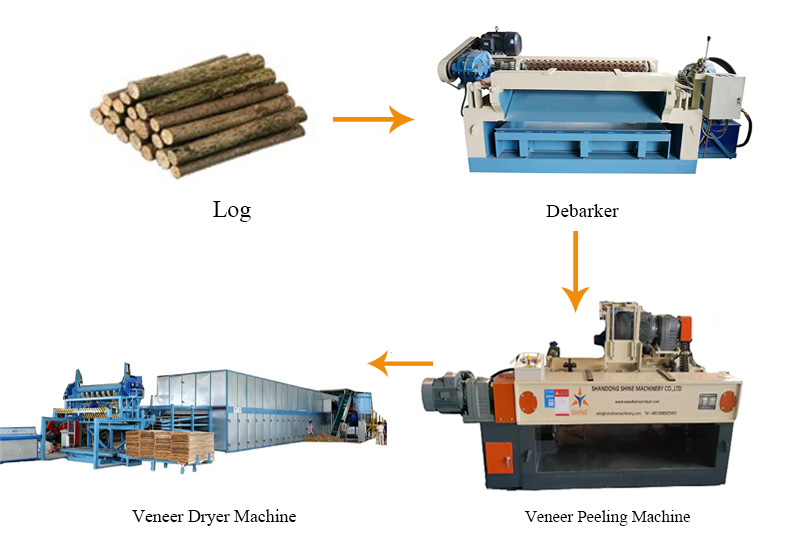

Veneer dryers are made use of to dry the slim layers of wood that are bonded together to create sheets. This procedure is essential in the manufacturing phase to prevent warping, fracturing, and to guarantee the end product is smooth and sturdy.

The Evolution of Plywood in Modern Industry

As industries grow and develop, the need for sturdy and effective materials like plywood increases. The intro of specific equipment, such as knife grinders and veneer dryers, has significantly boosted the top quality and consistency of the item. These innovations have made plywood a lot more obtainable and dependable for a variety of applications.

The Importance of Knife Grinding Machines

Knife grinding machines are essential in plywood manufacturing. They aid preserve the intensity of the cutting blades, making certain specific and tidy cuts. Keeping the blades in leading condition decreases product waste and enhances the general top quality of the end product.

Why Knife Grinder Machines Matter

Investing in a knife grinder machine is essential for makers. Without effectively preserved blades, the reducing process becomes ineffective, which can result in unequal sheets and more waste. These makers aid enhance productivity and ensure high-quality cuts with marginal effort.

The Role of Veneer Dryers

Veneer dryers play an essential role in the production procedure. By drying out the slim timber layers appropriately, these devices help avoid bending and ensure a solid bond between layers. The drying process contributes to the sturdiness and level of smoothness of the ended up item.

Frequently Asked Questions (FAQs)

1. Can it be used outdoors?

Yes, particular sorts of plywood are created for exterior usage. Exterior-grade plywood is treated to withstand wetness, making it ideal for weather-exposed applications.

2. What is the strongest type?

Marine-grade plywood is taken into consideration the best because of its resistance to wetness and rot. It's suitable for exterior applications like boats and docks.

3. Can it be stained?

Yes, it can be tarnished, however it needs to be secured properly later to safeguard it from dampness and wear.

Conclusion

Knowing the size and flexibility of plywood is simply the start. By using the right devices, like knife grinders and veneer dryers, you can guarantee that your jobs turn out perfectly and efficiently.