About us

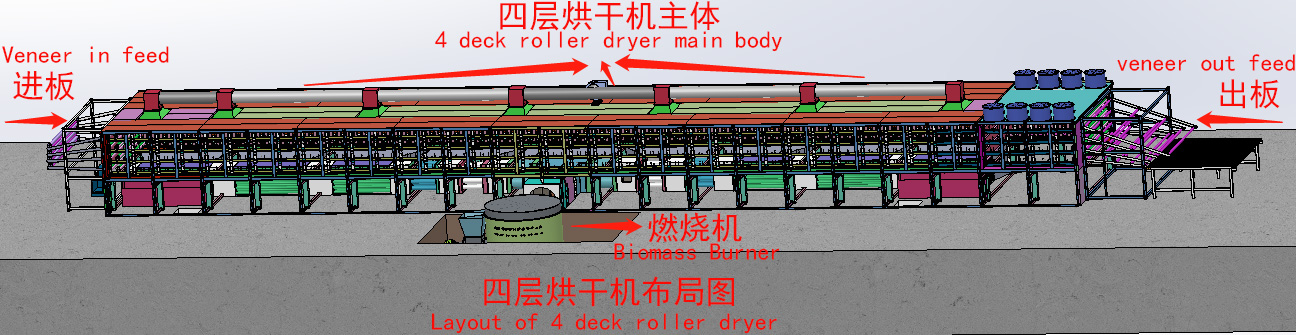

Shandong Shine Machinery Co.,Ltd is a large-scale manufacturer specializing in R&D of wood veneer drying & veneer sheet peeling equipment. With decades fo growth, Shine Machinery has continuously improvved our equipment based on customer feedback. From out first dryer in 1999 to today's 4th generation of eco-friendly veneer prodution line, we are dedicated to relentless innovation, providing superior soutions.

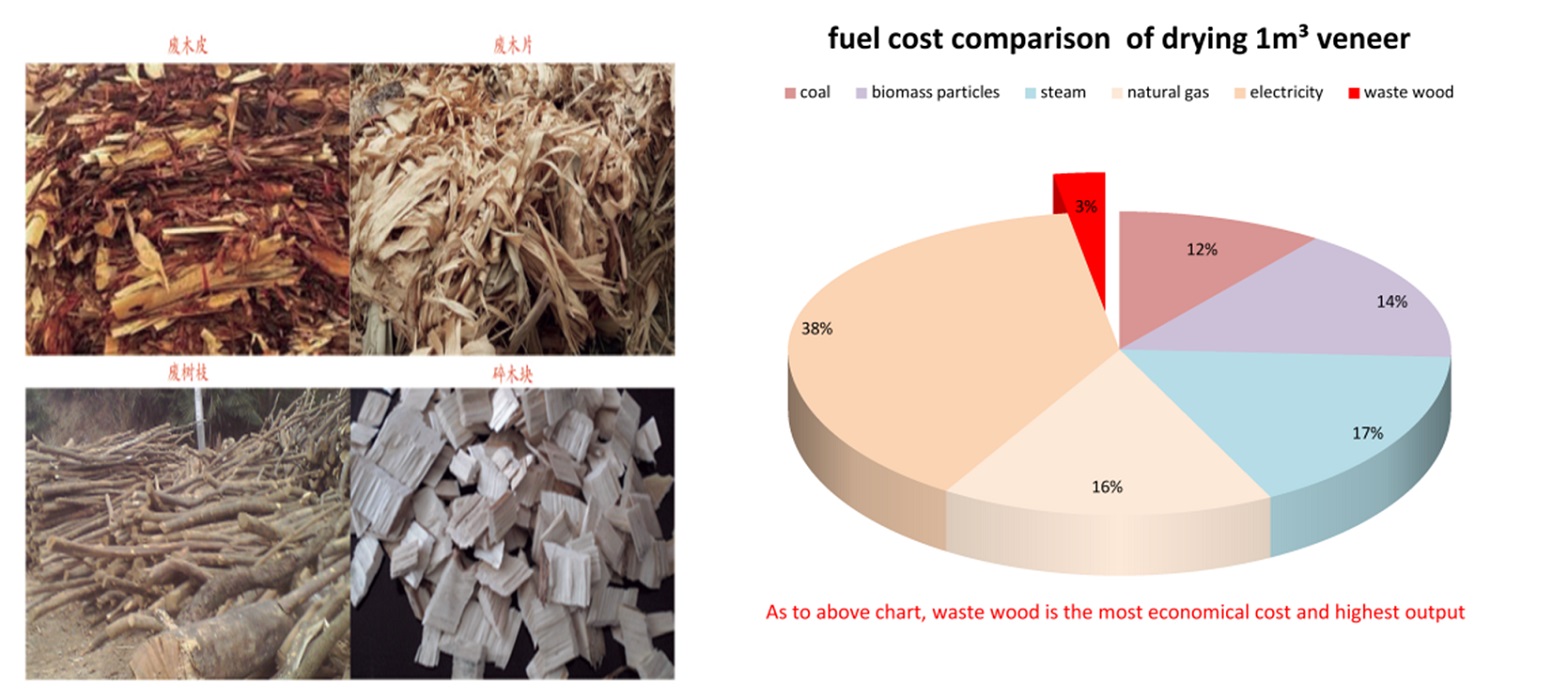

Shine is the first enterprise to propose the concept of "Green Veneer" production in China. We know the most crucial points of every process from log handling to high-quality terminal products. Shine aims to create values for our customers, the society, and the whole world. As a pioneer in low-carbon technology for woodwokring machinery, we actively promote a green future for the industry.

Shine has s fabulous reputation with our customer base and also gained regular customers. Shine roller veneer dryers are sold to various provinces in the country, and exported to Russia, Latvia, Romania, Brazil, South Africa, several Southeast Asia countries, and other regions.

Learn more

News

Shandong Shine Machinery Co.,Ltd is a large-scale manufacturer specializing in R&D of wood veneer drying & veneer sheet peeling equipment. With decades fo growth, Shine Machinery has continuously improvved our equipment based on customer feedback. From out first dryer in 1999 to today's 4th generation of eco-friendly veneer prodution line, we are dedicated to relentless innovation, providing superior soutions.

Shine is the first enterprise to propose the concept of "Green Veneer" production in China. We know the most crucial points of every process from log handling to high-quality terminal products. Shine aims to create values for our customers, the society, and the whole world. As a pioneer in low-carbon technology for woodwokring machinery, we actively promote a green future for the industry.

Shine has s fabulous reputation with our customer base and also gained regular customers. Shine roller veneer dryers are sold to various provinces in the country, and exported to Russia, Latvia, Romania, Brazil, South Africa, several Southeast Asia countries, and other regions.

Learn more